Sheet Metal Rolling

We are living in the industrial age and unless you are from the moon then you know this for sure. There are so many things that make up these industries among the raw materials. Whereas there are so many types of industries today we are going to look at the metallic industries. We are going not dwell so much on the industries but rather on one product of these industries which sheet metal. In this text, we are going to look at how this material is produced as well as the other things you need to know about the same.

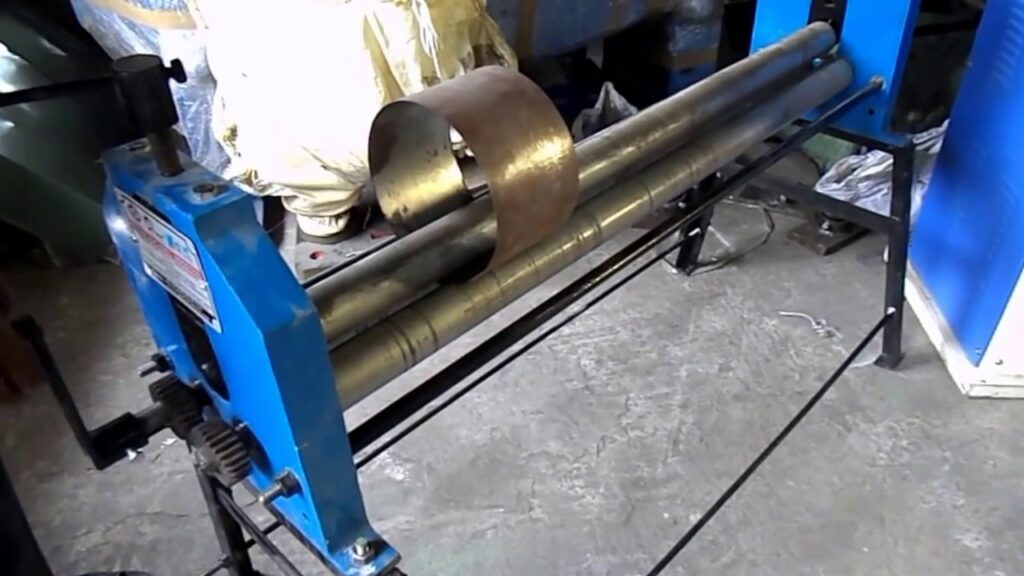

One thing about sheet metal is that it takes a lot of work to get to the useful piece that is sold to companies for use. One way of coming with this product is by a process known as Sheet metal rolling. This a process where sheet metal is rolled into a cylindrical shape and used for whatever purpose it is intended for. The outcome of this process depends on so many things. One of these things is the machines that are used to carry out this process. Now, if you think the results out of this process are standard then you are very wrong, they are not. In fact, we have cases where this process is carried out in a way so wrong that it warranted a repeat process.

Should such a thing occur then the responsible company will suffer losses due to the usage of more materials. One thing that determines the outcome of this process is the machines that carry out the procedure. If you are going to carry out this process and aiming for the best results then you need the best equipment. Not just any machines can get you the best results from this process but only those from Contract Manufacturing Specialists of Illinois. This is the only known place where you can get the best machines that will work well for you and get you the results you need.

Well, that is just about the machines you need and how well they can serve you. Again, we are not going to dwell so much on the machines but instead, we are going to look at the sheet metal and just some few things about the same.

It is not so wrong to say more and more people are now turning to the use of sheet metal to create various products. Many industries today cannot do without sheet metal and this is due to many reasons among them durability and the versatility of this material. The thickness of sheet metals varies from one metal to the other but these materials are mainly divided into two distinctions which are heavy plate and thin gauge.

Why you need to go for sheet metal

The fact that sheet metal is widely used is what is leading to an increase in its popularity. If you have never used this material in any way then you need to go for it. There are so many reasons that make sheet metal such a better material compared to the others and that is what we are going to look at today.

Sheet metal is less expensive

This is something that you cannot take away from sheet metal. The material is not as costly as the other alternatives. If you look at it from the angle of material cost as well as processing then you will notice that sheet metal is less expensive. Unlike the other materials, sheet metal does not come with those costly tooling procedures that the other materials come with. If you are producing sheet metal on a large scale then you are more likely to spend less compared to the other people producing the other alternatives.

Sheet metal allows you to buy what you need to use

One thing about the other materials is that no matter what you need to use them for, you will have to start with a block of the material. This is not really a good idea as much of this material will be lost in the fabrication process. If you look at it keenly then you will realize that this will cost you more in the long run.

However, this is not the case with sheet metal. Sheet metal only allows you to buy what you need to use for whatever products you need to create. This means with the fabrication of sheet metal, there is so much of this material that will go to waste. If we have an unused piece of sheet metal then you can use that for another project later on. The shaving produced by the machines can be kept somewhere for recycling later on. Other than the low cost that you spend on this entire project, you are also left with some other materials for recycling.

If you look at things this way then you will learn that sheet metal is less expensive compared to the other materials. The advancement in technology and more so by computers has made the fabrication of sheet metals like Sheet metal rolling to be carried out easily.

The common types of sheet metal

There are so many types of sheet metal, most people only know of steel as the only type of sheet metal but there are other types as well. There are very many of these parts used in so many areas either as alloys or any for that matter.

However, the real choice of the sheet metal material depends on the final product of the same material. There are so many things that set these types of steel aside like corrosion, resistance cost among others. There some materials that are found in the precision of sheet metals like the ones listed below.

Stainless steel

Stainless steel comes with so many grades that you can choose from. For instance, under this category, we have the Austenitic which is a non-magnetic type of steel that contains high chromium levels as well as nickel and low carbon levels. Other than that, we also have the Ferritic which is a magnetic but non-heat-treatable steel that contains chromium but with very little nickel. Whereas the other types of steel are used for structural uses, this one is used for non-structural use.

Its main use of decorative applications where aesthetics is a major concern. These metal types are majorly found in 400 series stainless steel. Lastly, we have the Martensitic which is a group comprising of chromium-containing no nickel that is developed with the aim of providing steel grades that are resistant to corrosion as well as being hardenable through heat treating to a wide range of strength level and hardness.

Cold rolled steel

This is a process through which hot trough which hot rolled steel is processed further to smooth the finish as well hold tighter tolerances during the formation process.

The pre plated steel

Sheet metal material comes in the following forms. It is either hot-dipped galvanized steel or galvanised steel which is galvanized and then later on annealed. The process of galvanizing simply entails the application of protective zinc coating with the view of preventing it from rust.

Sheet metal finishing

There are so many ways that you can use to finish sheet metal. Depending on the material chosen, finishing is mainly used to protect the materials from corrosion and rust. Other than that, we also have other finishing tactics that are done for aesthetic reasons.

We also have cases where finishing can be done to achieve these two objectives. We also have those finishing procedures which include simple alterations to the material surfaces.

Sheet metal is such a wonderful material used for many purposes. If you are in the metal fabrication process then this is one material that you need to adopt due to its many benefits. If you are looking for a place to get the machines for this process then you need to visit Contract Manufacturing Specialists of Illinois. This is one place where you can get the best machines for this process.

The resources that have allowed us to offer the best quality services at affordable rates. If you need any of them, feel free to request a free quotation from our team now. We have a highly skilled team of professionals who are more than willing to make your dreams come true. You can be sure of getting the real value for your money and reporting a high level of customer satisfaction when you choose to contact our company.

Our core offerings and services at Contract Manufacturing Specialists of Illinois includes, but is not limited to, the following:

We service multiple cities throughout the state of Illinois. We provide all the services listed above, and much more in every city throughout Illinois.

If you don’t see your city listed or a specific service listed, don’t worry. All you have to do is contact us by either giving us a call or filling out our online contact form. Then we’ll discover what are some of the top solutions for you, your business, and executing a solid solution.